Save time on repairs, Improving compliance, Reduce injuries

Preventative maintenance saves money and increases the safety and reliability of your revenue generating assets. Yet for most fleet managers today, time-sensitive breakdowns and the worsening tech shortage makes sticking to a PM schedule more and more challenging. Equipping technicians with the tools they need to get PMs and Repair work done safely, ergonomically and efficiently is more critical than ever when it comes to the uptime of your fleet. That’s where the LiftPoint LTX comes into play. Designed to service the widest array of Class I-IV material handling fleets on the market, the LTX enables technicians to change load wheels, service drive tires, perform inspections, and find and fix leaks in a fraction of the time it takes with traditional jacks. In the case of one Fortune 100 service tech, the LTX turned a 2 hour job (which required a second technician for 15 minutes) on the floor into a standing, 8 minute job for one man.

MATERIAL HANDLING LIFTS

Quantum Lift is a proud provider of LIFTPOINT material handling lifts, offering innovative and dependable solutions for safely lifting and positioning heavy loads across industrial and commercial environments. LIFTPOINT products are engineered for precision, durability, and operator safety, making them ideal for manufacturing facilities, warehouses, and maintenance operations. Whether handling engines, components, or equipment, these lifts deliver smooth, controlled performance that enhances productivity and reduces downtime. With Quantum Lift’s expert guidance, installation, and support, customers can trust that their LIFTPOINT systems will deliver long-lasting performance and efficiency in even the most demanding applications.

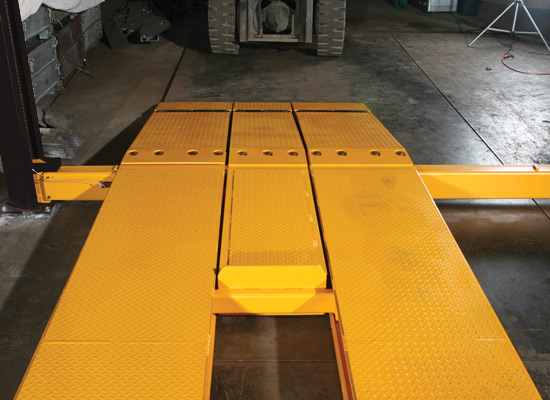

MODELS LTX-18 / LTX-22 / LTX-30

18,000 lbs, 22,000 lbs & 30,000 lbs Capacity Material Handling Device – Two Post Lift

MOBILE COLUMN FORKTRUCK ADAPTER

28,000 lbs Capacity Material Handling Device Service Lift Adapter

GET YOUR TECHS OFF THE GROUND

13,000 INJURIES

PRODUCTIVITY

PRODUCTIVITY

- Gets material handling equipment in & out of the repair bays faster, leading to 100% fleet utilization.

- Allows full access to underside componentry for faster, better inspections, PMs and repairs

- Tires and load wheels hang free for faster changes, especially when used with the TD-350 wheel dolly

- A more ergonomic design to keep your techs off the ground–reducing fatigue and limiting both chronic injuries and reportable accidents

Each year, technicians experience over 13,000 non-fatal “lost-time incidents” at work. The majority of these are due to chronic injuries, leading to more sprains, strains, and tears.

These injuries increase in frequency with age & on tasks with poor ergonomics.

EMPLOYEE RETENTION

The average technician leaves the field within 1 year of hire, posing a major challenge to operators. Better ergonomics means less fatigue, less pain, and happier technicians that are easier to retain. Investing in your technicians means investing in their workstations.

BEFORE LIFTPOINT

AFTER LIFTPOINT

SAFE LIFTING IN 60 SECONDS

The Only Lift Built to Service Forklifts, Pallet Jacks, Reach Trucks & More

TWO POST LIFTS

Drive-On Lifts